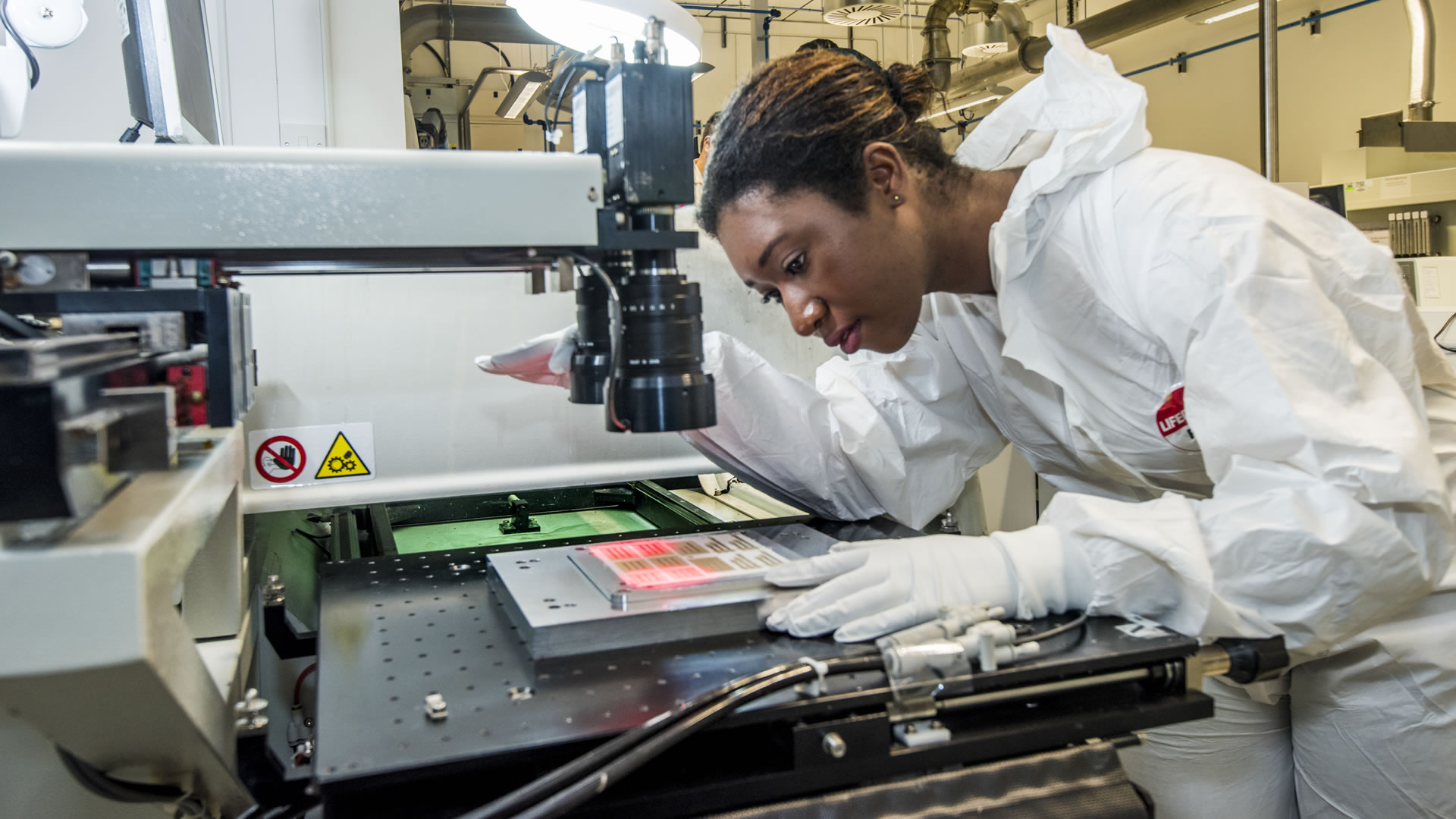

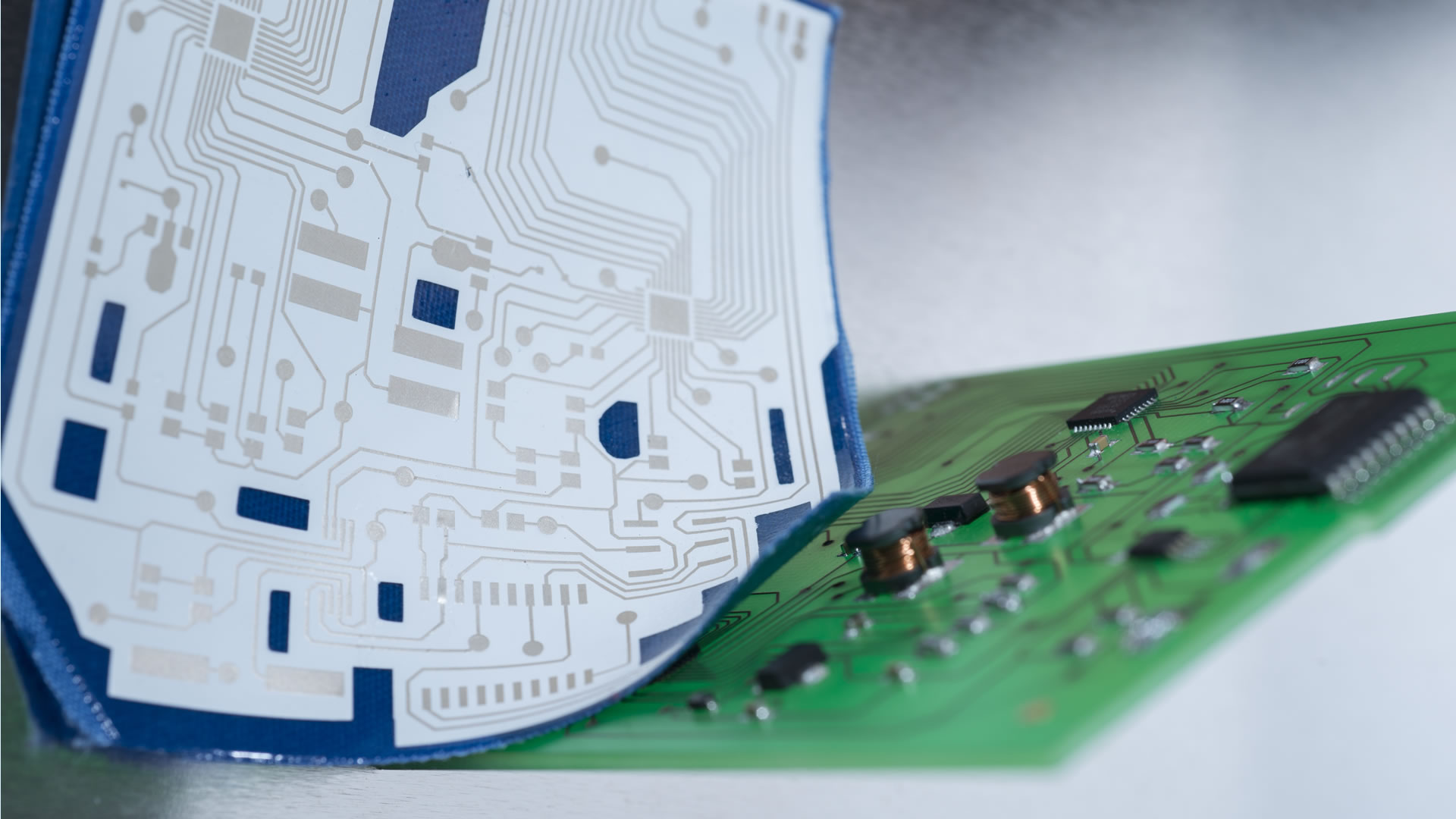

The Printed Electronics and Materials Laboratory realises novel thick-film electronic sensors, actuators, circuits and systems printed with a screen printer or inkjet printer on a variety of substrates using commercial and in-house inks and pastes. The printed devices developed within the facility include micropumps, heaters, multi-layer flexible printed circuit boards, accelerometers, gas and liquid sensors, electroluminescent displays, pressure sensors and energy harvesters. A bead mill is used to develop our own printed electrically active materials, and materials analysis tools are used to study the effects of particle size and distribution upon electrical performance.

Teaching

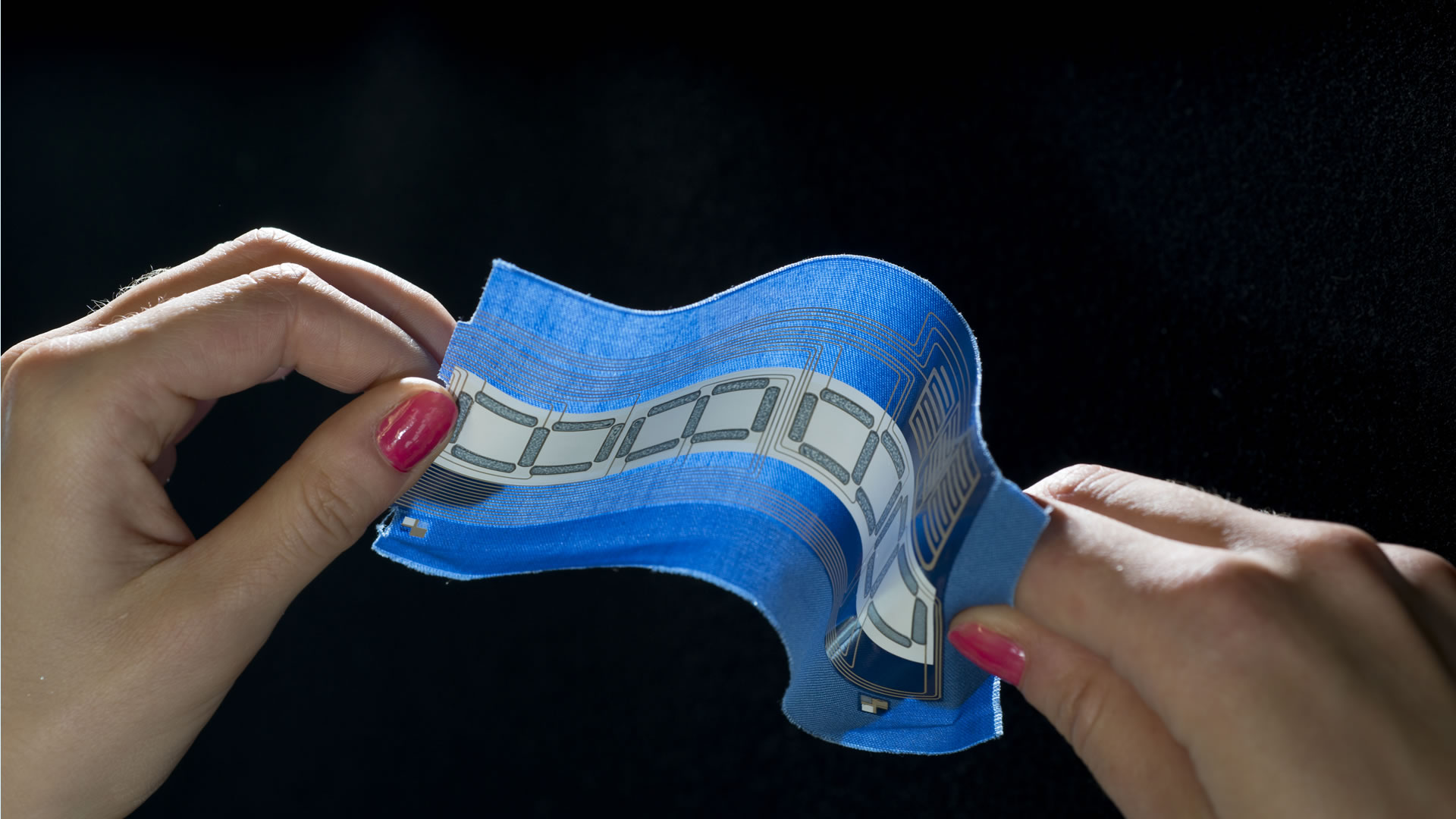

This is primarily a research facility. However, we do offer the opportunity for some third-year undergraduates and MSc students under the supervision of associated academics to work in this laboratory to fabricate devices and conduct experiments. In fact, one of our undergraduates produced the world’s first all screen-printed electroluminescent watch display on fabric.

Facilities and equipment

We have capabilities at the macro-micro interface, enabling the production of larger scale devices in semiconductor, metallic and piezoelectric materials.

Specialist equipment includes:

DEK248 screen printer

Dimatix DMP2831 inkjet printer

Netzsch Microcer Bead Mill

Malvern Mastersizer

Malvern Zetasizer

Research

The laboratory is used extensively by PhD students and post-doctoral researchers for their projects and research into printed thick-film materials. Areas of interest include the research and design, printing and integration of:

- electronic sensors (e.g. accelerometers, gas and liquid sensors, pressure sensors)

- actuators (e.g. micropumps)

- electroluminescent displays

- multi-layer flexible printed circuit boards

- heaters

- energy harvesters

We are able to develop our own electrically active inks and pastes , and analyse the properties of those materials.

Business and Enterprise

The laboratory facilities are used in partnership with a range of industrial collaborators. Our spin-out company Smart Fabric Inks offers a comprehensive platform technology for electronic textiles, with a broad portfolio of functional materials and the expertise to develop new solutions.